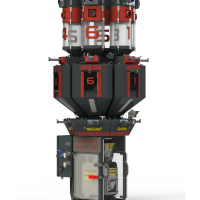

CWD

GRAVIMETRIC BLENDER &

GRAVIMETRIC EXTRUSION CONTROL

CWD

GRAVIMETRIC BLENDER &

GRAVIMETRIC EXTRUSION CONTROL

The first made in Greece dosing system for Extruder!

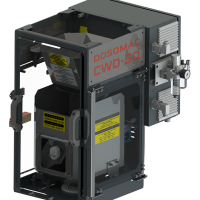

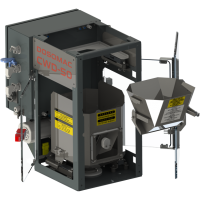

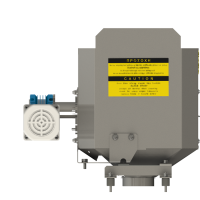

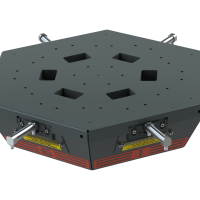

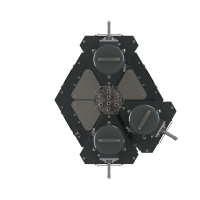

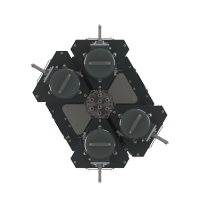

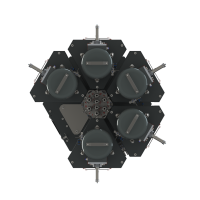

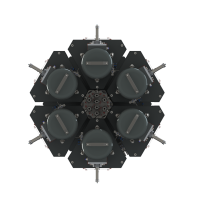

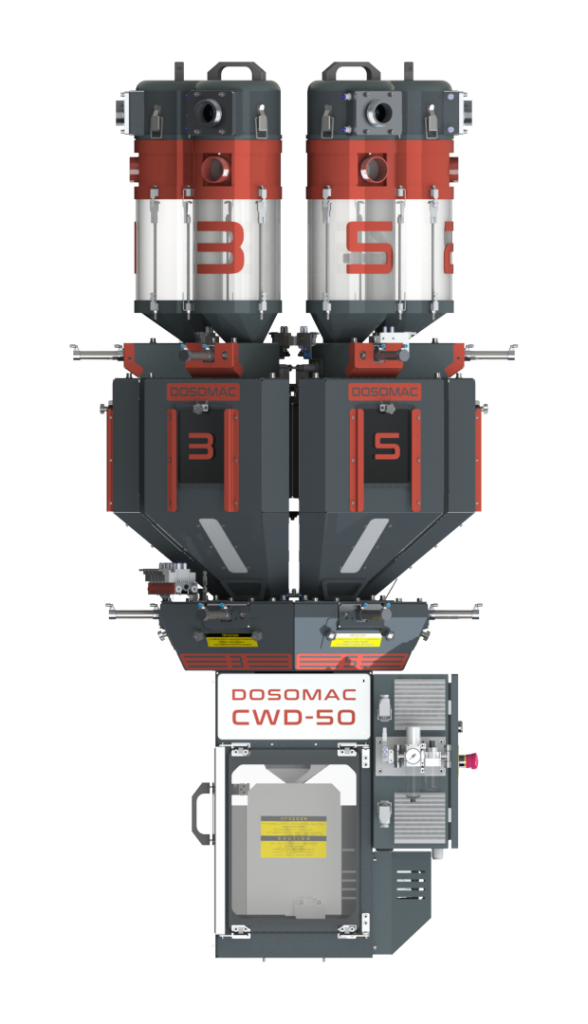

A new GAIN-IN-WEIGHT dosing system with a capability of mixing up to 8 materials! It was manufactured with state of the art manufacturing technologies and operates with top-level performance PLC in conjunction with a perfectly structured software.

The first made in Greece dosing system for Extruder!

A new GAIN-IN-WEIGHT dosing system with a capability of mixing up to 8 materials! It was manufactured with state of the art manufacturing technologies and operates with top-level performance PLC in conjunction with a perfectly structured software.

The Ultimate Software in the service of the Ultimate Hardware

The structure of the software allows for maximum performance of the Siemens PLC in conjunction with the 24bit analysis of the control card of LOAD CELLS. The dosing control accuracy and constant LOSS-IN-WEIGHT control of the Extruder’s production reach the maximum limits of existing technological capabilities.

The Ultimate Software in the service of the Ultimate Hardware

The structure of the software allows for maximum performance of the Siemens PLC in conjunction with the 24bit analysis of the control card of LOAD CELLS. The dosing control accuracy and constant LOSS-IN-WEIGHT control of the Extruder’s production reach the maximum limits of existing technological capabilities.

Applications

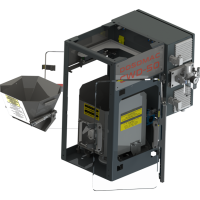

DOSOMAC CWD can be easily installed and operate in Extruder: film, sheet metal, pipes, profiles, wires and injection.

Applications

DOSOMAC CWD can be easily installed and operate in Extruder: film, sheet metal, pipes, profiles, wires and injection.

Profit and productivity with amortisation in less than 52 weeks!

Advantages of using DOSOMAC CWD Weigher and Technical characteristics

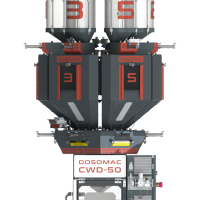

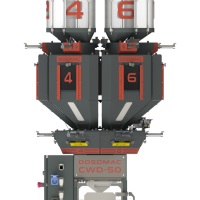

GRAVIMETRIC BLENDER & GRAVIMETRIC EXTRUSION CONTROL.

The first designed and made in Greece dosing system for Extruder & Injection!

Profit and productivity with amortisation in less than 52 weeks!

A new GAIN-IN-WEIGHT dosing system with a capability of mixing up to 8 materials! It was manufactured with state of the art manufacturing technologies and operates with top-level performance PLC in conjunction with a perfectly structured software designed by us based on international standards and optimum operation.

The Ultimate Software in the service of the Ultimate Hardware. The structure of the software allows for maximum performance of the Siemens PLC in conjunction with the 24bit analysis of the control card of LOAD CELLS. The dosing control accuracy and constant LOSS-IN-WEIGHT control of the Extruder’s production reach the maximum limits of existing technological capabilities.

Applications: DOSOMAC CWD can be easily installed and operate in Extruder: film, sheet metal, pipes, profiles, wires and injection.

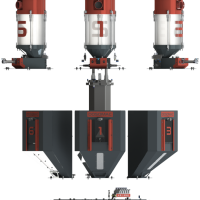

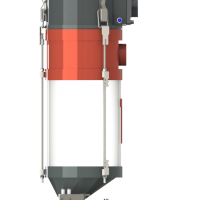

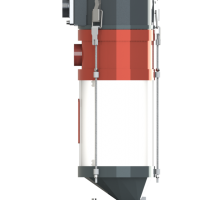

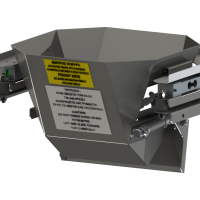

- DOSOMAC CWD height from support table: 2.05m.

- Hopper capacity: 32Lt

- Bach Bin: 3Lt.

- Air circuit: 4-5 bar.

- Production: up to 500Kg / Hr.

- Dosing and mixing, with per gram weighing of all materials, with absolute accuracy and continuous mixing.

- Saving at least 20% in master batch and additives.

- Mixing of all materials with 0.1% accuracy.

- Per gram weighing of material during the feeding of the Extruder and automatic production control.

- Extrusion Control Automatic set up and operation of the Extruder. The operator sets the desired film thickness and kilos per hour in the management software of DOSOMAC CWD . DOSOMAC CWD does the rest automatically.

- The system controls the weight and thickness of the product obtained with 0.5% accuracy.

- 50% reduction of start time and switching of production conditions.

- Minimizing of raw materials wastage, as well as elimination of problems related to production.

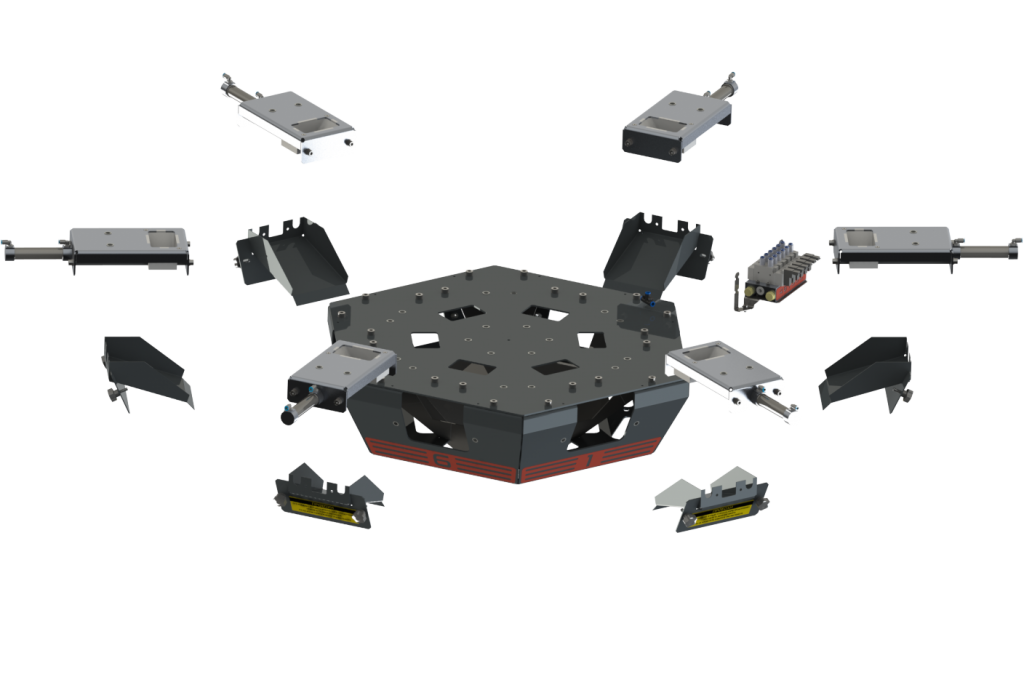

- Easy access to all mechanical parts of DOSOMAC CWD is ensured for cleaning and maintenance.

- Easy to use, due to its simplified interface.

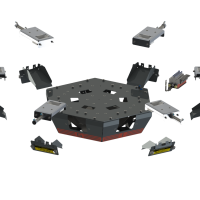

- Fully modular design for easy conversion from 2 to 8 materials.

- Reduced installation cost with integrated factory wiring.

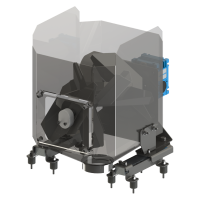

- Fully automated system for material loading to receivers with use of three-phase vacuum pump – Vacuum 2.2kw/3kw/5.5Kw.

- Receivers capacity 8Lt.

- Integrated mixing bin with specially designed stirred for optimal homogenisation of the blend. Mixing Bin 10Lt.

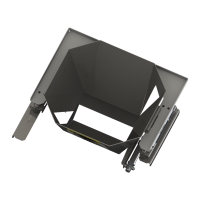

- DOSOMAC CWD support table for reduced vibrations (enhanced accuracy), as well as for easy access of the operator for maintenance purposes.

- 36,3 Lt buffer for connection between the cannon entrance and DOSOMAC CWD with material exit on the side.